After Carpet

Project: Materials and Methods Studio class, individual project (14 weeks)

Assignment: Explore the use and manufacture of new and/or unique materials utilizing industrial remnants supported by material experts, scientists, and field specialists in applied design and manufacturing.

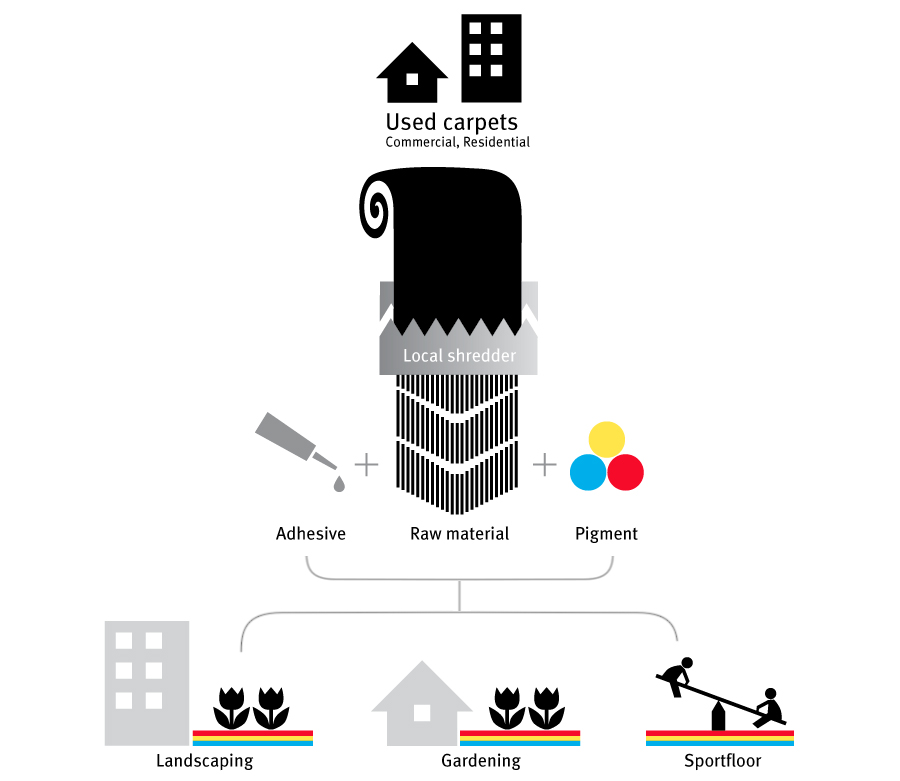

Rethinking the used carpets

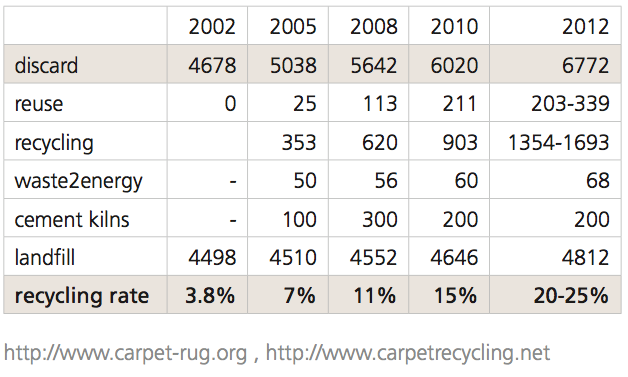

Traditionally there has not been a good business model for recycling indoor carpeting.

Of course, carpets can be refurbished and sent back to the original or new installation for reuse. Some carpet manufacturers build facilities connected to their manufacturing plants to burn or gasify old carpet into steam as energy source. Some strip down old carpeting, melt it and make new carpet yarn. Recycled carpet backing can be transformed into picnic tables, truck dock bumpers, or furniture. Unfortunately, due to the current slowdown in new home construction and renovation, the manufacture of any type of floor covering is off by as much as 30% to 40%, leaving less product to be recycled.

In addition, the cost of collecting and transporting used carpeting to recycling facilities is often cost prohibitive. With the development of new uses for recycled carpeting, profitability can be put back to the process.